Ready for shipment 410SS random packing support plate in

distillation tower

1. The random packing support plate arrangements according to tower

inner diameter (part table):

| Item | Inner Dia.

mm | Support Plate Dia. mm | Support Plate Sections | Support Ring Width mm | Support Ring Thickness mm |

| 1 | 300 | 290 | 2 | 30 | 10 |

| 2 | 400 | 380 | 2 | 30 | 10 |

| 3 | 500 | 480 | 2 | 30 | 10 |

| 4 | 600 | 580 | 3 | 30 | 10 |

| 5 | 700 | 680 | 3 | 30 | 10 |

| 6 | 800 | 780 | 3 | 40 | 10 |

| 7 | 900 | 880 | 3 | 40 | 10 |

| 8 | 1000 | 980 | 3 | 40 | 10 |

| 9 | 1100 | 1080 | 4 | 40 | 10 |

| 10 | 1200 | 1160 | 4 | 50 | 10 |

| 11 | 1300 | 1260 | 4 | 50 | 14 |

| 12 | 1400 | 1360 | 4 | 50 | 14 |

| 13 | 1500 | 1460 | 5 | 50 | 14 |

| 14 | 1600 | 1560 | 5 | 50 | 14 |

| 15 | 1700 | 1660 | 5 | 50 | 14 |

| 16 | 1800 | 1760 | 6 | 50 | 14 |

| 17 | 1900 | 1860 | 6 | 50 | 14 |

| 18 | 2000 | 1960 | 6 | 50 | 14 |

| 19 | 2100 | 2060 | 7 | 50 | 14 |

| 20 | 2200 | 2160 | 7 | 50 | 14 |

| To be continued. |

When the tower inner diameter is over 2600mm, main bearing beam

under the beam supporting plate is required.

2. Basic requirements on random packing hump support:

- It has enough strength and rigidity, and can support the quality of

packing and liquid holding as well as the operating pressure, etc;

- It has an opening ratio greater than the void ratio of the packing

layer to prevent flooding at this position;

- The structure is reasonable, which is conducive to the uniform

distribution of gas and liquid phases, small resistance and easy to

disassemble.

3. Random packing support plate in distillation tower Introduction:

It provides physical support for the tower packing and the weight

of the liquid holdup. The packing support plate must allow both the

down-flowing liquid phase and up-flowing gas phase to go through

freely. Usually we use gas injection type of support plate for

random packing. There is separate passage for liquid and gas. And

we use flat bar welded grids as structured packing support. The

tower packing support plates have very high open area for liquid

and gas, so doesn’t add any significant pressure drop.

4. Random packing support plate structure in distillation tower

The commonly used packing supporting devices are grid plate type,

beam type, etc. But in Hualai factory, we develop some new types,

for which we cover crimped mesh on simple plate welded hump

structure.

The packing supporting grid plate composed of parallel slats is

simple in structure and convenient in manufacture, which is

commonly used in small tower. Grid type support plate is only used

in small tower because of its small opening rate and bigger flow

resistance to gas and liquid than other types.

5. Random packing support plate tecknical info:

At present, the best supporting device for random packing is beam

type supporting plate, which adopts beam type gas jet structure. It

is composed of beam-shaped elements, which are perforated on steel

plates with many long holes. The support plate is of gas-liquid

split type, in which the gas is ejected from the holes at the upper

part of each beam element, while the liquid flows down from the

holes at the lower part, avoiding the increased resistance when the

gas-liquid flows reversely through the same hole. Moreover, it can

provide more than 100% of the free cross-sectional area of the

tower, so gas-liquid flow resistance is small, and it is conducive

to gas-liquid redistribution. The flow capacity of the support

plate can reach 200 m3 / (M2 · h), and the maximum pressure drop is only 69 Pa.

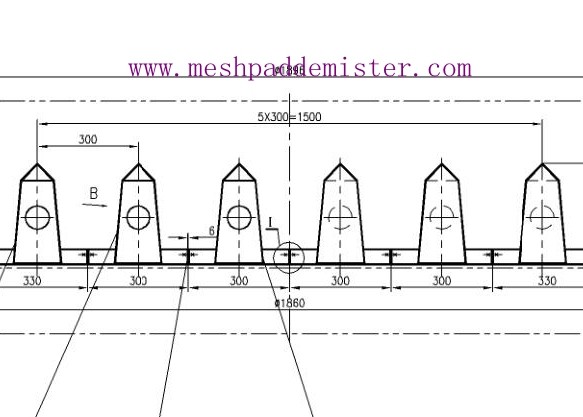

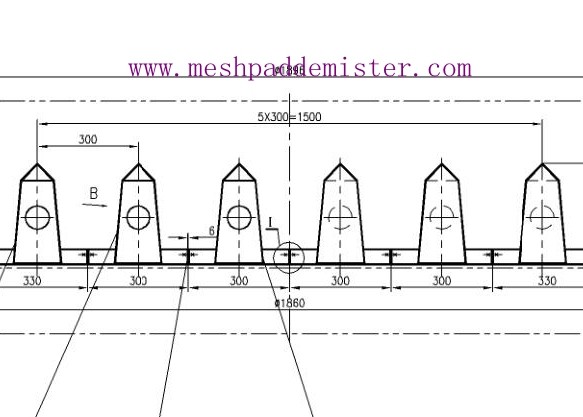

6. Random Packing Hump Support design drawing

Welcome your contact with your private tower internals plan or

ideas!